Webpage

Digital Twins in Manufacturing: Revolutionizing Operations and Driving Innovation

In today's fast-paced manufacturing environment, introducing digital twins has marked the beginning of a new era of innovation, efficiency, and optimization. The estimated global revenue of the digital twin market was USD 10.1 billion in 2023 and is projected to soar to USD 110.1 billion by 2028, achieving an impressive compound annual growth rate (CAGR) of 61.3% from 2023 to 2028. A digital twin is a virtual counterpart to a physical product, process, or system, facilitating real-time monitoring, analysis, and optimization. This groundbreaking technology has significantly altered the manufacturing landscape, enabling organizations to make informed, data-driven decisions, curtail expenses, and enhance overall performance. This blog explores the concept of digital twins in manufacturing and elucidates their transformative impact on the industry.

The Benefits of Digital Twins in Manufacturing

1. Enhanced Operational Efficiency

Digital twin technology is a powerful tool for boosting operational efficiency. Providing real-time monitoring, predictive maintenance, and data-driven decision-making helps companies track performance, identify issues early, and make informed choices. It leads to optimized resource allocation and minimized downtime. The technology's ability to simulate scenarios and predict equipment failures further contributes to operational smoothness, cost savings, and enhanced productivity.

2. Product Development and Innovation

Digital twins are revolutionizing the product development process. They save time and costs by offering virtual prototyping, testing, and customization capabilities. Moreover, digital twins enable companies to optimize production processes and personalize products based on customer needs, driving innovation. This combination of reduced time-to-market, improved efficiency, and enhanced customization strengthens a company's competitive edge in the market.

3. Improved Collaboration and Training

Digital twin technology fosters better collaboration and training. A visual representation of assets and processes facilitates team communication and enhances understanding. Moreover, the technology enables realistic training simulations using AR/VR experiences, improving employees' skills and safety protocols. Its remote monitoring and troubleshooting capabilities further reduce downtime, enhancing overall performance and efficiency.

4. Sustainability and Environmental Impact

Digital twin technology is a crucial enabler of sustainability. Optimizing energy usage and evaluating environmental impact help companies reduce waste and minimize their carbon footprint. Moreover, digital twins support circular economy practices, such as closed-loop manufacturing, by optimizing resource usage throughout the product lifecycle. In summary, the technology contributes significantly to sustainability efforts by promoting efficient resource usage and sustainable product design.

5. Improved Safety

The advanced capabilities of digital twins significantly enhance workplace safety. They can accurately simulate hazardous scenarios and identify potential safety risks, enabling companies to implement appropriate safety measures before accidents occur. By monitoring real-time data, digital twins assist in the early detection of safety hazards, thereby reducing the likelihood of accidents and injuries. This proactive approach to safety safeguards employees and helps companies comply with stringent safety regulations. Ultimately, a safer workplace fosters happier, more productive employees and a more successful business.

Real-World Applications of Digital Twins in Manufacturing

1. Production Optimization

Digital twins are critical in optimizing manufacturing processes by simulating real-world conditions and predicting their effects on production. They help schedule, improve material flow, and optimize resource allocation, enhancing efficiency and reducing operational costs. By harnessing the power of data analytics and machine learning, digital twins can adjust to evolving conditions and deliver valuable insights to drive ongoing process enhancements.

2. Supply Chain Management

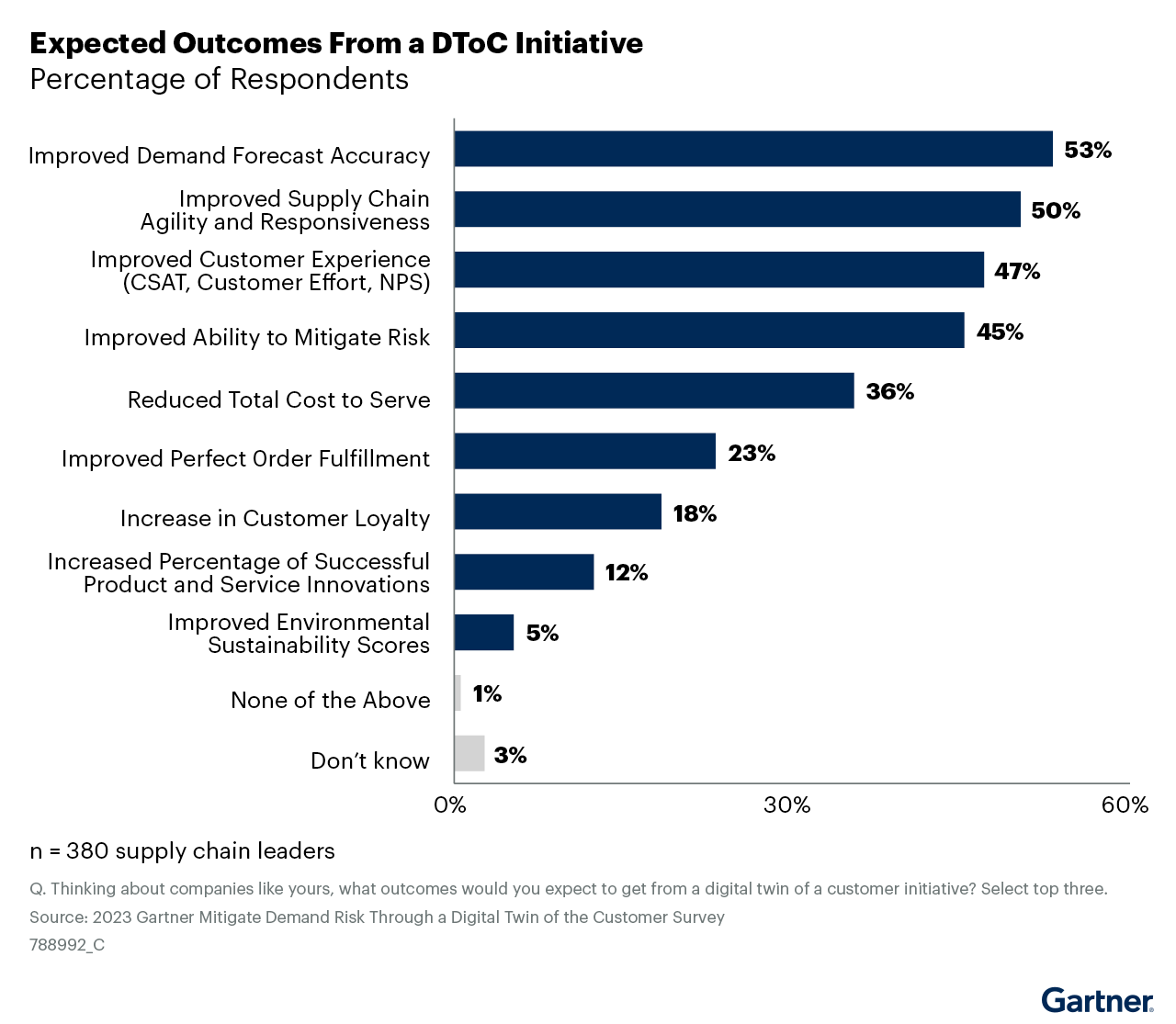

Digital twins are instrumental in managing and optimizing real-time supply chain operations. They monitor inventory levels, track transportation routes, and optimize warehousing strategies, ensuring timely deliveries and reducing costs. Digital twins enable manufacturers to identify inefficiencies, streamline operations, and improve customer satisfaction by providing an inclusive view of the supply chain. Gartner's survey of 380 supply chain leaders showed that while 60% are piloting or planning to implement a digital supply chain twin (DSCT), only 27% intend to incorporate a digital twin of the customer (DToC) as part of their broader digital strategy.

Source:Gartner

3. Product Design

Digital twins are revolutionizing product design by enabling virtual prototyping and testing. They allow manufacturers to simulate different design scenarios, evaluate their performance, and identify potential issues before production begins. This technology streamlines the time and expenses linked to physical prototyping, expedites the design iteration process, and guarantees that the end product adheres to quality guidelines and customer demands.

4. Asset Management

Digital twins provide real-time insights into the condition and performance of equipment and assets. They monitor critical parameters, predict maintenance requirements, and recommend optimal maintenance schedules, reducing unplanned downtime and improving asset reliability. By enabling predictive maintenance, digital twins extend the lifespan of equipment, optimize maintenance costs, and ensure uninterrupted production.

5. Quality Control

Digital twins are indispensable in monitoring and maintaining product quality throughout manufacturing. They collect and analyze data from sensors and IoT devices, identify defects and anomalies, and provide insights into the main causes of quality issues. By enabling real-time quality monitoring and analysis, digital twins help manufacturers detect and rectify quality issues early, ensuring that only high-quality products reach customers.

Future Trends of Digital Twins in Manufacturing

1. Integration with Other Technologies

Digital twins will increasingly integrate with emerging technologies like IoT, AI, and blockchain. This integration will enhance data collection, analysis, and decision-making capabilities, leading to more advanced predictive maintenance, optimization, and automation.

2. Edge Computing

With the growing complexity and volume of data generated by digital twins, there will be a greater emphasis on edge computing. This decentralized approach to data processing will enable real-time insights and actions, reducing latency and improving overall system performance.

3. AR and VR

AR and VR technologies enhance digital twins' visualization and interaction capabilities. Users can interact virtually with physical assets and processes, enabling better collaboration, training, and decision-making.

4. Cybersecurity

As digital twins become more central to manufacturing operations, cybersecurity will become a critical concern. Manufacturers need to establish robust cybersecurity protocols to protect sensitive data and uphold the integrity and security of their digital twin ecosystems.

5. Real-time Optimization

Digital twins will evolve to provide real-time optimization of manufacturing processes. Advanced algorithms will continuously analyze data, identify inefficiencies, and suggest optimization strategies, enabling manufacturers to respond quickly to changing conditions and improve overall efficiency.

Conclusion

Intelliswift offers comprehensive solutions for Digital Twins in the manufacturing industry. Our services include strategic consulting, data acquisition and integration, data modeling and visualization, machine learning and analytics, custom application development, training, and support. We also provide additional services such as security and data privacy solutions, cloud-based deployment, and AR/VR integration. Intelliswift's expertise helps manufacturers harness the potential of digital twins to enhance efficiency, optimize operations, and gain a competitive edge. Contact us to learn more about how digital twins can revolutionize your manufacturing operations.

Sanjay Kalra, VP, Digital Transformation and Head, Alliances

Sanjay is a highly experienced subject matter expert in Information Technology, Product Engineering, Customer Experience, Cloud, Automation, Data Analytics, and AI – which enables him to serve as a trusted advisor to enterprises and growing organizations.